Application

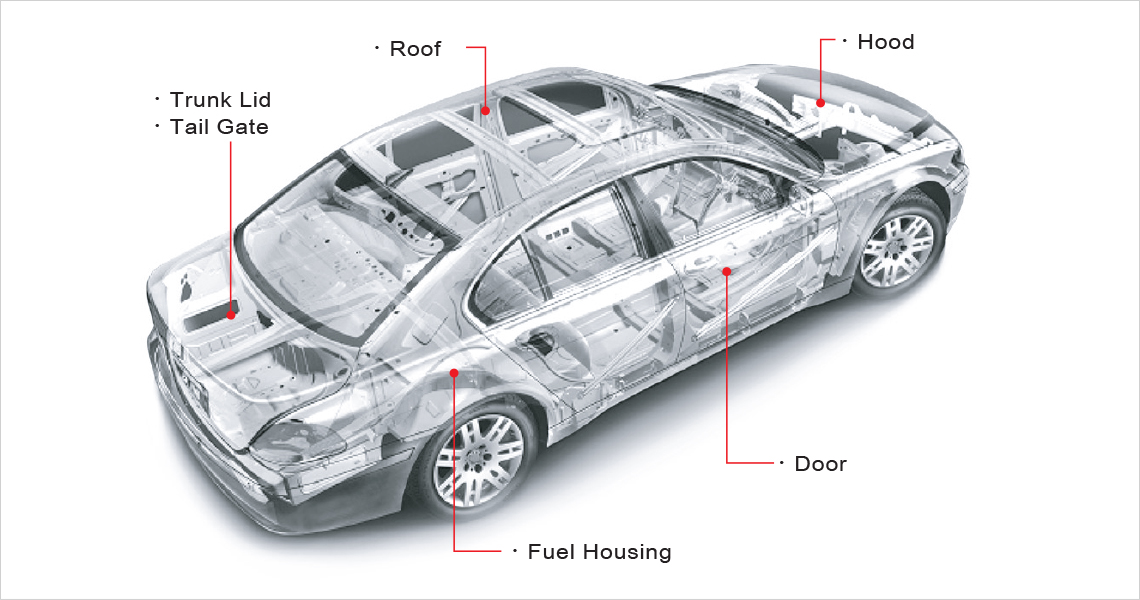

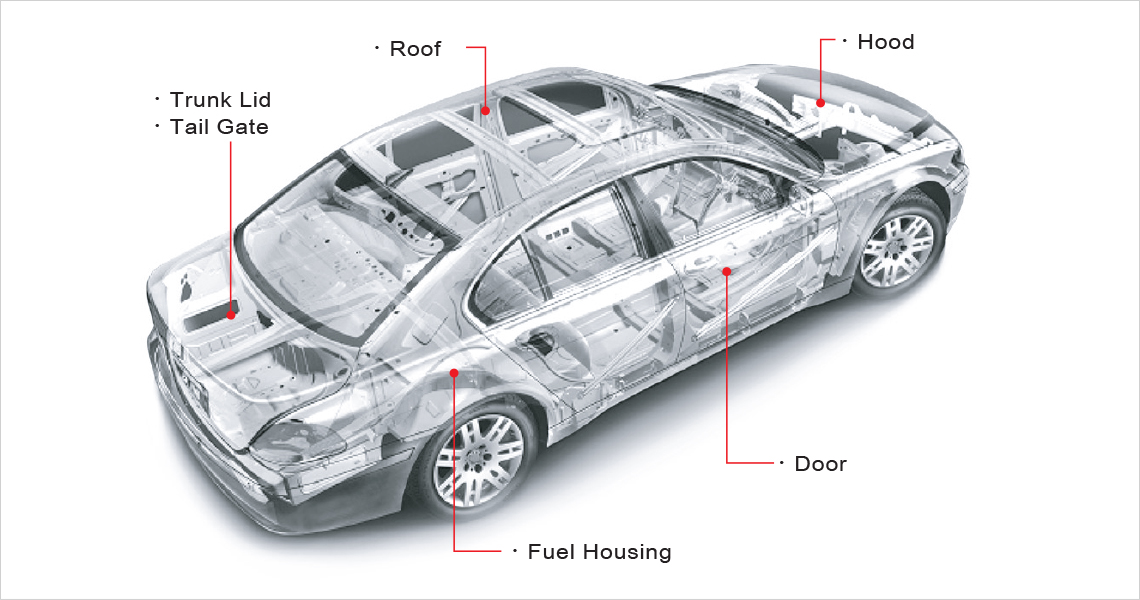

Mastic Sealing is designed for filling, adhesive, vibration control by foaming and heat-hardened sealer while passing thru dry-oven after dispensing Mastic Sealer in between outer panel and inner panel of moving part with exclusive Sealant Equipment.

Main Ingredient : Synthetic rubber

Viscosity : 2,000~4,000PS

Dispense Temp. : 34~38℃

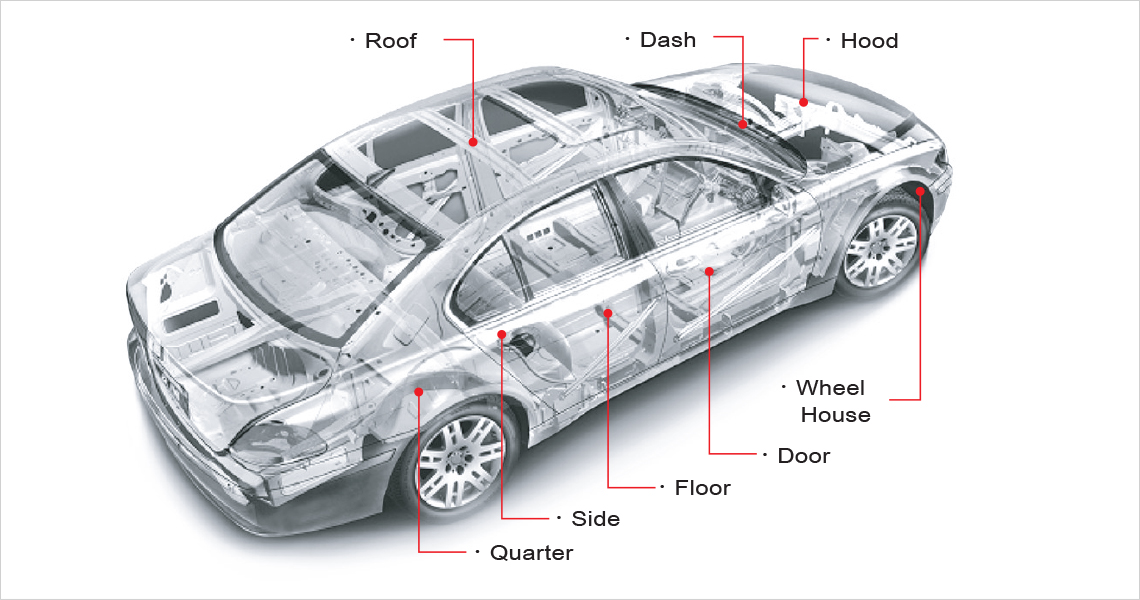

Spot Sealing is designed for water-tightness, anti-corrosion by vulcanization, filling, adhesive while passing thru dry-oven after dispensing by exclusive Spot Sealer Equipment and spot welding on spot welding panel conjunction part.

•Main Ingredient : Synthetic rubber

Viscosity : 2,000~2,500PS

Dispense Temp. : 34~38℃