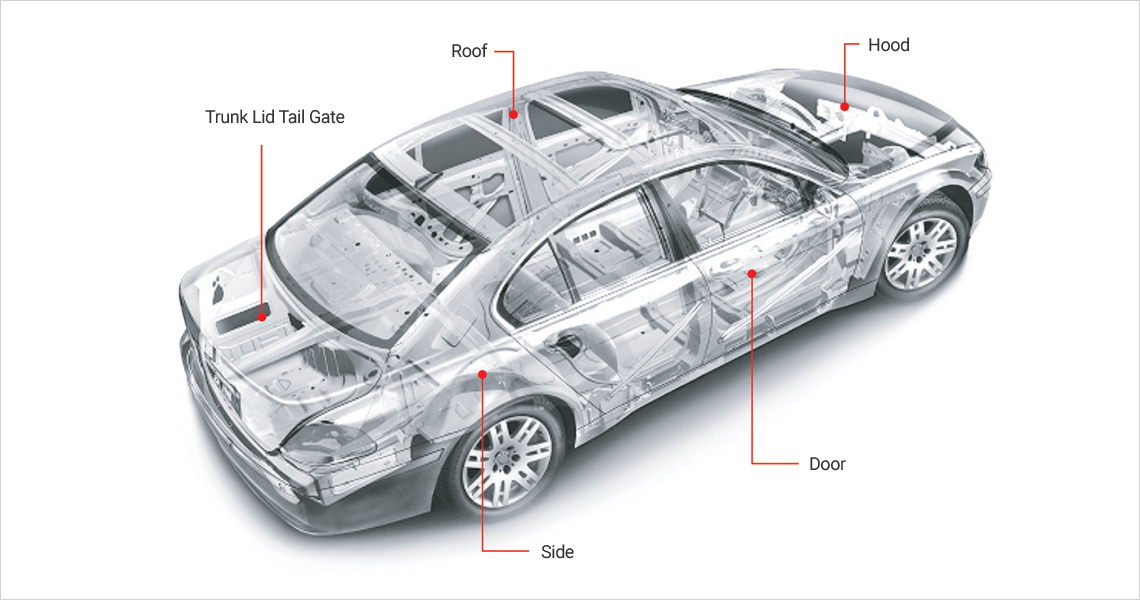

Application

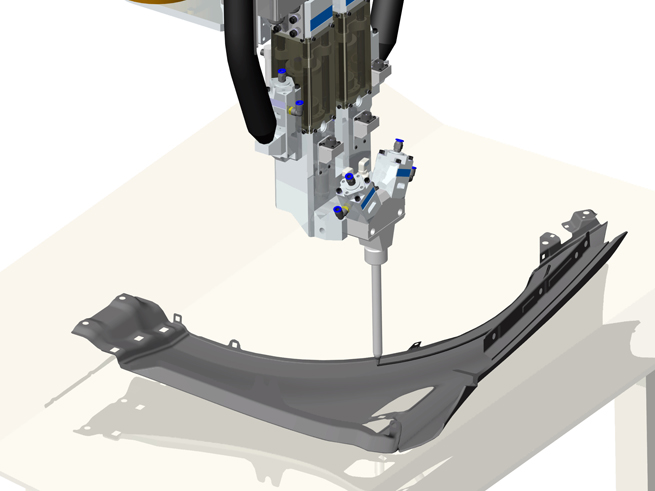

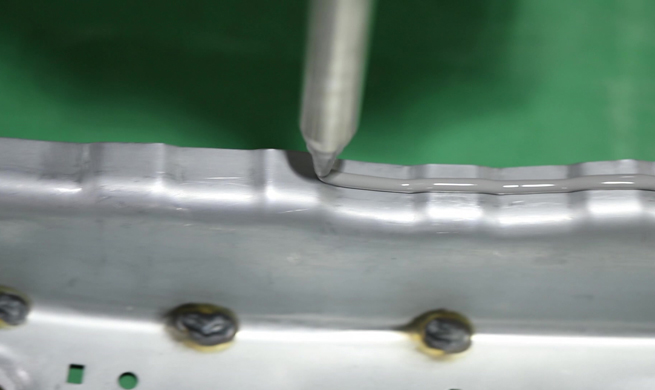

2K (two-liquid type) sealing method has capacitated bonding of dissimilar materials, which were not applicable to existing structural sealer due to natural hardening at room temperature by mixing of base and hardener, and it is applied to prevent deformation that may occur during the process movement by applying partially to the body production.

Resin and Hardener are pumping at proper temperature, mixing of quantitative ratio, controlling of application amount, and after applying extrude pattern, then it enables to bond at room temperature by matching other joint materials.

BASE(Resin): uses vary according to material characteristics and it is made of epoxy/ urethane resin.

HARDENER: acts as a catalyst to cause hardening at room temperature when mixed with base (resin) at a specified ratio.

Hardening condition : Generally within 15 minutes after bonding. 30minuest to 4 hours hardending under ntaural condition (depending on materials)

Epoxy series: Applicable to body-line, Rising bond strength when passing through painting oven.

Urethane series: Application to assembly-line, not applicable to pass painting oven.

Applicable to bonding of dissimilar materials (Example) Aluminum + Steel

Carbon + steel etc.

Dispense Type : Extrude

Dispense Volume : Max. 50cc X 2EA (MAX)

Dispense Flow Rate : Max. 20cc/sec

Dispense Pressure : : Max. 200bar

Dispense Speed : Max. 700mm/sec

Flow Rate Control Type : Servo Motor volume control

Flow Rate Control Precision Accuracy : ±5%

Viscosity Compensation Control : : ±30%

Panel~Nozzle Gap:: 1.0~3.0mm

Mixing Rate : 1.00~10.00 : 1 (User Parameter)

Mixing Type : Static mixer